Tipper Refuse Trailer

MORE PAYLOAD

East refuse trailers have excellent “empty weight,” and still give you the strength to handle the stresses of hauling refuse every day. With the East Genesis® smooth-sided design you get an extra 5 cubic yards over external post.

EASIER TO MAINTAIN

It costs less to repair and maintain East refuse trailers. Wall repairs are not as noticeable because the trailer walls are welded individually. Typically, wall repair doesn’t require top rail removal.

MORE VERSATILITY

For more profitability, the combination of lightweight and high strength gives you versatile and flexible load options.

HIGHER RESALE VALUE

East has earned the reputation for quality that consistently brings a higher resale value.

Tipper Refuse Trailer

The East Tipper Refuse Trailer stays on the job longer, reducing downtime and increasing profits. By incorporating lightweight and longer-lasting components into each and every trailer, East has earned the reputation of time-tested performance and higher resale value.

The East design uses high-quality aluminum. The unique 2-inch thick, double-wall extruded aluminum panels that are tongue-and-groove design, are robotically welded together, vertically inside and out for superior strength and resistance to twisting.

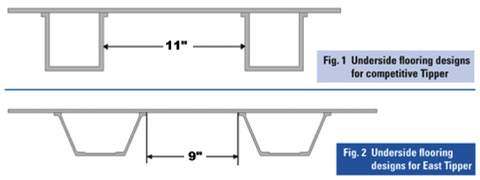

The flooring of an East Tipper is supported by V-shaped cross members 9 inches apart. This means it will have more support front-to-rear and less susceptibility to floor wave.

Stronger Floor

Competitors use either I-beam supports or U-channel supports, spaced 11″ apart (Fig. 1). The flooring in an East Tipper is supported by V-shaped cross members 9 inches apart (Fig. 2). This means an East Tipper will have more even support — front-to-rear — and less susceptibility to floor wave. All with less cross members — and less weight than you would find on competitive tipper trailers.

East V-shape cross members provide a major performance advantage – more structural support. East refuse trailers have less unsupported space in the trailer floors. That translates into more support in top-loading operations, and more support if the customers run a fork lift into the trailer.

Greasable tailgate hardware is designed for longer life, reducing maintenance. Landing gear features extra-wide wings, diagonal support braces and C-channel cross members to withstand frequent shocks.

The East Tipper is designed to maximize payload and still provide the strength to handle the stresses of hauling refuse day in and day out in the harshest conditions.

The East external post Tipper has been a long-time leader in performance and durability. The durable design of the East external post Tipper, proven to perform with top efficiency and minimum downtime, gives you a better bottom line.

Standard Features

The subframe uses an 11-inch extruded aluminum I-beam, adding durability for strength and to reduce maintenance.

The subframe uses an 11-inch extruded aluminum I-beam, adding durability for strength and to reduce maintenance.

East’s latching system with bolt-on receivers allow for easy maintenance.

East’s latching system with bolt-on receivers allow for easy maintenance.

Subframe has an integrated bumper with push block that’s designed for greater durability.

Subframe has an integrated bumper with push block that’s designed for greater durability.

Top hinges and side-swing hinges are greaseable. Greaseable tailgate hardware is designed for longer life, reducing maintenance.

Top hinges and side-swing hinges are greaseable. Greaseable tailgate hardware is designed for longer life, reducing maintenance.

Filtered glad hands prevent contamination of the airlines.

Filtered glad hands prevent contamination of the airlines.

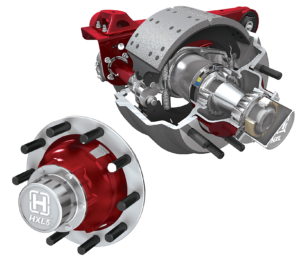

The READY-TO-ROLL HXL5® is designed to maximize uptime and efficiency and reduce wheel-end maintenance. The preassembled and adjusted HXL5 features a premium seal, high-performance synthetic semi-fluid grease and a PRECISION320™ spindle nut system, which allows for ultra-precise bearing adjustment.

Fifth-wheel assembly is designed for maximum load-bearing strength with a stainless steel band to protect against galvanic corrosion.

Fifth-wheel assembly is designed for maximum load-bearing strength with a stainless steel band to protect against galvanic corrosion.

Landing gear features extra-wide wings, diagonal support braces and C-channel cross members to withstand frequent shocks.

Landing gear features extra-wide wings, diagonal support braces and C-channel cross members to withstand frequent shocks.

This standard lightweight landing gear provides increased durability and strength. A durable internal gearbox and standard JOST gear allows for easy interchangeability. The HX150 Magnum includes a galvanized inner lower leg and crank handle, and an aluminum outer leg. With a 200,000 static rating and a 70,000-lb. lift, the 5-year maintenance free landing gear comes standard with a 10-Year Warranty. See JOST Extreme Duty Double Cushion Foot for HX150 Magnum Series Landing Gear.

This standard lightweight landing gear provides increased durability and strength. A durable internal gearbox and standard JOST gear allows for easy interchangeability. The HX150 Magnum includes a galvanized inner lower leg and crank handle, and an aluminum outer leg. With a 200,000 static rating and a 70,000-lb. lift, the 5-year maintenance free landing gear comes standard with a 10-Year Warranty. See JOST Extreme Duty Double Cushion Foot for HX150 Magnum Series Landing Gear.

The standard JOST Extreme Duty Double Cushion Foot provides the forgiveness and reliability that a tough environment calls for. With twice the cushion inside the shoe, a trailer can withstand a greater impact without risking damage to the landing gear. It reduces stress when a leg impacts the ground with significant force, protecting the integrity of the internal working of the leg. It retrofits onto any current cushion foot landing gear.

The standard JOST Extreme Duty Double Cushion Foot provides the forgiveness and reliability that a tough environment calls for. With twice the cushion inside the shoe, a trailer can withstand a greater impact without risking damage to the landing gear. It reduces stress when a leg impacts the ground with significant force, protecting the integrity of the internal working of the leg. It retrofits onto any current cushion foot landing gear.

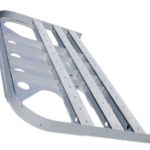

Rear-extruded light panel integrated into gate.

Rear-extruded light panel integrated into gate.

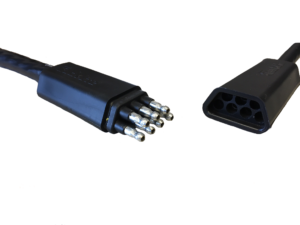

To guard against corrosion, the harness has been designed as a closed system by integrating a model plug with two sealing surfaces rather than just one.

To guard against corrosion, the harness has been designed as a closed system by integrating a model plug with two sealing surfaces rather than just one.

Ultra ONE® 22.5″ x 8.25″ aluminum wheel is standard. At just 39 pounds, the wheel is the lightest wheel in its class and strong enough for demanding applications.

Ultra ONE® 22.5″ x 8.25″ aluminum wheel is standard. At just 39 pounds, the wheel is the lightest wheel in its class and strong enough for demanding applications.

Optional Features

Customers have indicated that they have increased fuel savings when the gate is open when traveling empty.

Customers have indicated that they have increased fuel savings when the gate is open when traveling empty.

102-inch-wide hinged floor catwalk.

102-inch-wide hinged floor catwalk.

The door allows a driver access to the inside of the trailer without climbing a ladder.

Waterseal tailgates are available for traditional external post trailers.

All air tanks have cable-operated drains.

All air tanks have cable-operated drains.