Tipper Genesis®

The Tipper is typically used for high volume operations. East V-shape cross member provides major performance advantages since it has more structural support. East refuse trailers have less unsupported space in the trailer floors. That translates into more support in top-loading operations and more support if you run a forklift in the trailer.

No Center Crossbar

No center crossbar gets in the way in this tipper trailer. It’s faster, cleaner and more even loading and compaction throughout the trailer.

Stronger Floor

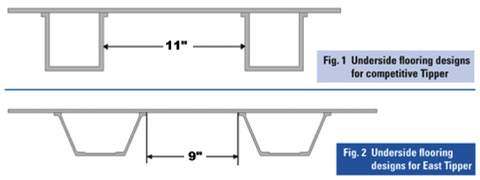

Competitors use either I-beam supports or U-channel supports, spaced 11″ apart. The flooring of an East Tipper is supported by V-shaped cross members 9 inches apart. This means it will have more support — front-to-rear — and less susceptibility to floor wave.

Competitors use either I-beam supports or U-channel supports, spaced 11″ apart (Fig. 1). The flooring in an East Tipper is supported by V-shaped cross members 9 inches apart (Fig. 2). This means an East Tipper will have more even support — front-to-rear — and less susceptibility to floor wave. All with less cross members — and less weight than you would find on competitive tipper trailers.

East V-shape cross members provide a major performance advantage – more structural support. East refuse trailers have less unsupported space in the trailer floors. That translates into more support in top-loading operations, and more support if the customers run a fork lift into the trailer.

Greaseable tailgate hardware is designed for longer life, reducing maintenance. Landing gear features extra-wide wings, diagonal support braces and C-channel cross members to withstand frequent shocks.