Frameless Dump Trailers

MORE PAYLOAD

East trailers have excellent “empty weight,” plus the strength and versatility to efficiently haul more than just bulk commodities.

EASIER TO MAINTAIN

It costs less to repair and maintain East dump trailers. Wall repairs are not noticeable because the trailer walls are welded individually. Typically, wall repair doesn't require top rail removal.

MORE STRENGTH

The East design uses high-quality aluminum in its composition. The unique 2-inch thick, double-wall extruded aluminum panels are robotically welded together vertically inside and out for superior strength and resistance to twisting.

HIGHER RESALE VALUE

East trailers have a reputation for quality that brings a higher resale value. Many East dump trailers remain on the highway over 55 years still providing reliable service no other manufacturer can match.

Frameless Dump Trailers

All East Dump Trailers are designed to maximize payload, and deliver strength and durability to meet the needs of all types of dump trailer applications. East trailers stay on the job longer, reducing downtime and increasing profits. By incorporating lightweight and longer-lasting components into each and every trailer, East has earned the reputation of having higher resale value.

Full Wrap-Around Bulkhead

The bulkhead is wrapped around the sides, back to the third floor cross member, transferring the hoist load to the side walls to reduce stress and potential cracking in tough applications. It aids air flow for improved fuel efficiency.

Strong Doghouse

Doghouse connects to an under-support system of U-shaped channels fastened and gusseted at critical torsion points. Stress is transmitted to neutral areas of the side walls, virtually eliminating stress cracks.

Lightweight Long-Life Upper Coupler

Replaceable stainless steel saddle receiver assembly bolted into an aluminum sub-structure for reduced tare weight and maximum durability.

Standard Features

Solid box extruded cross-member design provides support under floor seams for longer floor life. U-shaped cross members have special contact point flanges for extra support, and welds are positioned away from high-stress areas.

Solid box extruded cross-member design provides support under floor seams for longer floor life. U-shaped cross members have special contact point flanges for extra support, and welds are positioned away from high-stress areas.

Draft arm cross-member gussets are bolted – not welded – to allow the assembly the flexibility to give under normal stresses and vibrations, yet still maintain a positive connection.

Replaceable stainless steel saddle receiver assembly bolted into an aluminum sub-structure for reduced tare weight and maximum durability.

Replaceable stainless steel saddle receiver assembly bolted into an aluminum sub-structure for reduced tare weight and maximum durability.

The ¼-inch-thick rear corner posts wrap completely around top and bottom rails and interlock to add strength, reducing side-to-side distortion.

The ¼-inch-thick rear corner posts wrap completely around top and bottom rails and interlock to add strength, reducing side-to-side distortion.

Top hinges and bottom latch are bolt-on for easy replacement. Anti-corrosive coating and shims protect steel-to-aluminum connections.

Top hinges and bottom latch are bolt-on for easy replacement. Anti-corrosive coating and shims protect steel-to-aluminum connections.

Steel tailgate pins are zinc-plated for easy replacement. Anti-corrosive coating and shims protect steel-to-aluminum connections.

Steel tailgate pins are zinc-plated for easy replacement. Anti-corrosive coating and shims protect steel-to-aluminum connections.

Up to 50 pounds lighter per set and no external gearbox, the AX150 Alumilight includes a galvanized inner lower leg, crank handle and cross shaft. With a 160,000-lb static rating and a 55,000-lb lift, the landing gear comes standard with a 10-Year Warranty.

An air filter in the service and emergency line protects the ABS module from micro-particles entering the system.

To guard against corrosion, the harness has been designed as a closed system by integrating a molded plug with two sealing surfaces rather than one.

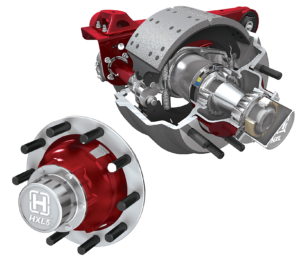

The READY-TO-ROLL HXL5® is designed to maximize uptime and efficiency and reduce wheel-end maintenance. The preassembled and adjusted HXL5 features a premium seal, high-performance synthetic semi-fluid grease and a PRECISION320™ spindle nut system, which allows for ultra-precise bearing adjustment.

Ultra ONE® 22.5″ x 8.25″ aluminum wheel is standard. At just 39 pounds, the wheel is the lightest wheel in its class and strong enough for demanding applications.

Ultra ONE® 22.5″ x 8.25″ aluminum wheel is standard. At just 39 pounds, the wheel is the lightest wheel in its class and strong enough for demanding applications.

Steel components are carefully prepared, primed and coated with a baked-on paint, producing a durable, attractive finish that resists corrosion.

Optional Features

Engineered for durability and enhanced performance, East offers a standard lift axle system or automatic lift axle system, developed for varying load operations.

Engineered for durability and enhanced performance, East offers a standard lift axle system or automatic lift axle system, developed for varying load operations.

Available in 12- and 20-inch widths, East coal/grain doors are equipped with UHMW plastic bearings and grease fittings at the pivot point, providing smooth, easy operation and low maintenance. For precise flow control, the door locks over center with the ability to lock at various positions.

Available in 12- and 20-inch widths, East coal/grain doors are equipped with UHMW plastic bearings and grease fittings at the pivot point, providing smooth, easy operation and low maintenance. For precise flow control, the door locks over center with the ability to lock at various positions.

The door allows a driver access to the inside of the trailer without climbing a ladder.

The door allows a driver access to the inside of the trailer without climbing a ladder.

ZMD air springs are designed to provide continuous damping over the life of the air spring. The shockless suspension reduces maintenance. Robust down stops provide maximum durability which reduces labor, costs and maintenance over the life of the trailer.

ZMD air springs are designed to provide continuous damping over the life of the air spring. The shockless suspension reduces maintenance. Robust down stops provide maximum durability which reduces labor, costs and maintenance over the life of the trailer.

An actuator handle located at the bottom rear of the body enables you to convert the tailgate from side swing-to-top swing and vice verse. The latch that engages and releases the top pin is hidden and protected inside the rear post.

An actuator handle located at the bottom rear of the body enables you to convert the tailgate from side swing-to-top swing and vice verse. The latch that engages and releases the top pin is hidden and protected inside the rear post.

The Side Swing Tailgate Guide Ramp Roller prevents top pin misalignment by guiding the gate and top pin back into position during closing, making the gate much easier and faster to close.

East has an unlimited list of Optional Features for Frameless Dump Trailers. Please contact East Sales.